Commercial helical pile setup looks sincere from a range. A small digger or skid guide turns a helical anchor right into the ground, a torque scale goes up, somebody shouts varieties, and a groundwork problem starts to settle down. What you perform certainly not observe coming from the fence line are actually the safety practices that maintain palms in one piece, devices upright, and the client's residential or commercial property unscarred. The work blends geotechnical judgment along with rigging, hydraulics, energized devices, and frequently a limited metropolitan jobsite. Mistakes grow quickly. Solid instruction, disciplined use of private defensive devices, and very clear methods guard staffs and also deliver resilient end results for commercial structure stabilization.

I have spent years around helical piles, resistance heaps, as well as micropiles on commercial websites where trades overlap as well as schedules press. A large portion of carrying out the work properly is refusing to reduce edges. The twist that confirms capability may twist wrists and ride steel right into electricals if managements and procedures break down. Putting in a helical tieback anchor with a basement define a busy property may make a mistake in three ways prior to morning meal: you can easily skip a laid to rest avenue, you can easily overload a wall if your preparing mistakes, or you can easily injure a worker standing inside the conoid of influence when the support finds a cobble. Security listed here is actually not a binder in a gang package, it is actually day-to-day muscle mass memory.

Why pile safety is various from regular jobsite safety

Concrete, framing, and MEP job stress reduces, cuts, as well as power threats. Commercial helical pile installation incorporates turning tons, subsurface unpredictability, and also the need to decipher comments coming from the ground directly. You are actually handling twist, central lots, as well as positioning while interacting around relocating devices. The exact same puts on commercial resistance pile installation as well as micropile installation. Each heap style has different equipment and also verification actions, yet they share hazards: spinning adapters, squeeze aspects near the drive head, piloting debris when a pin wiggles out under lots, and also the ever existing risk of reaching submerged utilities.

The mounted products likewise vary in exactly how they react to web site health conditions. Helical piles do not like huge obstacles yet radiate in filler and soft clays. Micropiles grow in heavy, variable dirts with rebar crates as well as grout, yet need orderly boring fluid monitoring and high-pressure cement devices. Protection stacks, driven with hydraulic jacks, operate gently in cramping city job however need to have strong preparing and reaction structures. That variety indicates your safety system have to be specific, not universal. A one-size tool kit talk performs not deal with tieback anchors passing through a basement wall structure, or even a twist cylinder that desires to end up on setback.

Training that prevents occurrences instead of chronicling them

Training begins before the first jug of gas fluid goes on the vehicle. The purpose is experience, not observance. You really want operators and laborers who know why a certain to-do list exists as well as what the varieties mean.

Start with equipment instruction adapted to the disk device. Operators should demonstrate comfort along with the digger or skid steer, yet also the torque motor, the adapter, and also the securing pin system. I have actually seen more near-misses coming from the incorrect pin in a drive head than from any single factor. If the twist link in between the electric motor and the helical pile is endangered, you switch several lots of steel in to a flail. Training includes hands-on practice placing, checking, as well as protecting disk pins, plus a workout on identifying wear in the adapter lugs and also difficult pins.

Next, cover soil behavior and also capability verification. The team needs to understand what torque correlation is, what a suitable Kt assortment resembles for the product as well as dirt, and exactly how to read through a twist dial or even digital transducer. They need to track when a growth in torque signals bearing and also when it shows obstruction. The exact same distinction applies to protection stacks. Installers need to realize when port tension reflects skin friction mobilization versus the stack instead of trusted edge bearing. For micropiles, show the distinction between cement takes that suggest really good stone outlets as well as those that show loss right into bone fractures. Skills below decreases need to over-torque or even over-drive, both of which raise risk.

Include energy situating and also proof training beyond referring to as 811. Private powers on business homes are actually commonly unmarked. Teams must practice potholing, low-vac daylighting, and making use of a multi-frequency locator. The installer operating the auger or even helical travel have to recognize how to continue when analyses are actually ambiguous. If you are putting up helical tieback anchors for a basement, show layout that steers clear of drainpipe lines, channel financial institutions, and also fire solution laterals. A power strike is actually a protection breakdown to begin with, then a routine problem.

Communication instruction issues. Hand signals, radio methods, as well as the words "knock off" need to have to be genuine tools. On a packed website, you will not hear a worker's shout over a high-flow auxiliary circuit. Our company teach to pause turning when anybody starts the ride scalp, and to explain in words torque and deepness out loud as they go up. The agent and the operator have to speak the same devices. I have actually checked out crews blend foot-pounds and kiloNewton-meters, a tiny complication that develops large danger when you require proof torque.

Finally, run emergency exercises that mirror the job. Rehearse a destitute palm at the ride head, a gas hose rupture, and also a wall surface penetration where particles blows back throughout helical tieback anchor installment. If you want to work third shift in an active center, take forty five mins to stroll the egress paths as well as verify lighting, lockout gain access to, as well as emergency assistance setting up under those lights problems. These drills transform intellectual strategies right into rehearsed steps.

PPE that fits the threats of turning steel and constrained systems

Hard hats, eye defense, gloves, safety and security footwear, high-visibility vests, and also hearing protection are actually the base. There are actually a handful of specifics for helical piles, protection piles, and also micropiles that ought to have attention.

Choose handwear covers that stabilize cut protection along with dexterity. Team participants should use small cotter pins and also twist sensing unit leads near rotating steel. Cumbersome handwear covers receive caught, thin handwear covers fail at the first burr. I prefer degree A4 to A5 hairstyle resistance with a tight belt. On tieback anchors and micropiles where cement lines and also tube fittings are in play, gloves need to additionally lose water and preserve grip when wet.

Eye and face defense requires to become much more than standard shatterproof glass when you are near spinning ports and grout. For workers at the ride head and any person aiding deal with areas, face covers over shatterproof glass minimize risk coming from taking flight plant range and little steel shards. Throughout micropiles, high-pressure grout may show off back coming from fittings. A face guard is actually affordable matched up to an eye injury.

Hearing defense is certainly not extra when high-flow hydraulics operate throughout the day. Consistent exposure at 85 to 95 dBA is traditional around sleek devices with travel heads, as well as certain tieback procedures surge greater. Well-fitted earplugs or even muffs always keep the workers sane and also communicative.

For workers taking care of tieback anchors, a loss protection program is commonly pertinent. Lots of industrial helical tieback anchor installations take place near cellar retaining walls or even outdoor walls along with quality reduces. If any person works within 6 shoes of an unprotected side or on scaffold for brace positioning, guarantee harnesses, anchors, as well as instruction remain in order.

Do not neglect basic skin layer defense. Gas oil as well as cement are abrasive as well as drying out. Nitrile disposables under job handwear covers always keep hands cleaner during the course of routine maintenance and also hose pipe improvements. Sunblock concerns on lengthy summer season installs, not just for comfort however considering that gotten rid of staffs rush to finish.

Procedures that bring in complicated installs feel routine

Safety grows when really good methods transform changeable states into foreseeable actions. The information might change for a health center add-on versus a storage facility fixing or even for a deep foundation repair under a busy retail flooring, however the backbone appears similar.

Pre-job preparation ties safety and productivity with each other. A solid plan consists of examined illustrations, validated stack areas, as well as a clear series that recognizes other exchanges. For commercial helical pile installation on a retrofit, assessment openings in slabs or even pathways are actually cut in breakthrough, and mess up monitoring is actually prepared so it carries out certainly not obstruct egress. If the work is commercial resistance pile installation, set up holding for jacks, response structures, and steel heap segments thus massive airlifts are actually reduced. For micropiles, designate room for cement silos and also a washout location, then secure drains coming from cement fines.

Utility space deserves its personal elapsed. After social marking, conduct personal situating and potholing. File confirmations for every stack or even tieback line within the grounds and also past the wall structure pipe. On certain campuses, fiber loops and chilled water pipes operate specifically where a tieback wishes to land. Switch the geometry early as opposed to improvisating with a drill head floating over unknowns.

Site commands around revolving equipment bring in the difference in between near misses as well as none in all. Develop a composed zone around the travel scalp. Simply the driver and one labelled assistant step inside. The assistant's job is to direct positioning, validate pinning, and also go through twist. Everybody else stays away from the rotating airplane. When installing longer segments of helical piles, cribbing and catch phrase keep portions dependable up until they are interacted along with the coupler. Never utilize your body as a backstop for a section that may stop during the course of engagement.

Torque surveillance is actually both quality control and also a security behavior. Calibrate the torque sign, whether technical or electronic, at a frequency suitable to use, normally month to month or by the supplier's advised hours. The agent announces torque at pre-agreed depth periods and also flags any kind of unexpected spikes or even reduces. Unexpected spikes may imply obstacle, and the right feedback is actually certainly not additional throttle. Time out, reverse turning briefly, clear spoil, and also reassess. Chasing torque through an obstruction bends rays, creates kept energy, and delivers shards when a bolt fails.

Alignment and also supporting for tiebacks and also resistance piles are entitled to additional focus. When installing helical tieback anchors via a structure wall, brace the wall properly just before administering bunch. A hurried crew can produce versus a wall that is not developed for the reaction, creating fracturing that switches a stablizing venture in to foundation crack repair. For protection heaps, confirm the reaction framework attachment and ground bearing capacity under the framework feets. The pressure demanded to press a commercial resistance pile into heavy coatings may shock you, and a changing framework may boot a jack out under pressure.

Micropiles incorporate boring liquid and also grout to account. Keep tubes short, fittings rated and checked, and also whip examine pressurized lines where suited. Pressure-test the line prior to manufacturing. Cement gains ought to be actually captured and also dealt with so they do not produce lapse dangers. A clean micropile create defends workers and also assists the QC engineer observe what matters: yield costs, pressure contours, and prepared times.

Breaks and also step-backs are part of treatment, not a privilege. When disorders change, quit as well as reassess. During one midtown venture, our team attacked an outdated lumber cot in filler at about eight shoes. The torque was unpredictable, as well as the travel electric motor was actually starting to chatter. It would certainly possess been simple to press through. Rather, we took the section, probed the location, and also switched pair of feet. The new site hit regular clay-based as well as hit concept torque swiftly. No damaged tools, no arched heap, and no surprise in the as-builts later.

Coordination along with developers and also inspectors

Safety expands when the area and the layout group field relevant information in both instructions. If the torque-to-capacity relationship for helical piles in the geotechnical report is based upon different helix geometry than what the provider supplied, the industry varieties will certainly exist to you. Carry disparities ahead just before creation. The same is true for resistance pile hoisting standards. If rejection occurs early around several areas, documentation tensions and also motion and also seek changed approval requirements or predrill instructions.

Inspectors are actually partners when you address all of them that way. They really want the exact same end result: predictable capacity, safe installation, and a document that withstands future analysis. Welcome all of them to the morning huddle. Program all of them the torque log layout or even the jack gradation certificates. When one thing weird series up in the dirt account, permit all of them see it as opposed to stashing it. That visibility prevents the sort of late-day fight that attracts individuals to miss steps.

Environmental and also residential or commercial property defense as a security goal

On office internet sites, the resident's atmosphere becomes part of staff safety. Tracking oil throughout a retail flooring, blasting cement fines in to a health center sky intake, or swamping a loading dock with drilling profits produces slip threats, online reputation damage, as well as occasionally OSHA focus. Plan containment. Additional control under gas electrical power packs is actually basic insurance policy. For helical piles and also helical anchors, stage absorbent mats around gas quick-connect factors and also torque motors. For micropiles, a washout pit or even sac maintains cement away from hurricane devices. For commercial foundation repair in occupied areas, isolate dust as well as resonance along with brief wall surfaces and also resonance displays. These measures bring in the room much safer for everyone on web site, featuring property dwellers who may walk within feet of your job zone.

Case details from the field

A college add-on required helical piles along an interior hallway. The drawings were actually alright, but the corridor concealed telecom channels that were never documented. Finds appeared tidy, which carried out certainly not mean a lot inside a structure. We produced an exclusive locator, confirmed the upright splitting up, then daylighted each stack site with a 6 inch dry out primary and suction. Two piles relocated through 12 ins, as well as our experts included sleeved protection around a pipe crossing. The extra half-day maintained the network live as well as our crew out of injury's means. The superintendent eventually acknowledged he was ready to press our team to continue without potholing. Instruction and also procedure held the day.

On a riverfront storage facility, resistance stacks were the correct option considering that the low space made helical equipment awkward. The response frameworks remained on timber floor coverings over fill. During the very first test, the mat switched when jack pressure slipped beyond 5,000 psi. Our company stopped, expanded the floor covering area, as well as steered temporary potatos to avoid moving. Afterwards, pressures climbed properly. A much less careful staff could have ridden the structure, adding shims and anticipating the most effective. The modified system took an hour and protected against a port ejection that can possess harmed pair of workers.

For a commercial helical tieback anchor installation on a cellar wall structure, the preliminary strategy possessed tiebacks angled at 15 levels more than parallel. As soon as core boring started, we found an outdated drainpipe series in the projected conoid. Our experts altered the angle to 10 levels and expanded the unbonded size, after clearing it with the engineer. The reduced slant pushed setup torque up through around twenty per-cent in the picked clay-based, as well as the torque electric motor managed it, but our PPE style mattered because the much higher torque and slower progression enticed individuals closer to the scalp. The supervisor shouted a tip as well as firmed up the controlled region. Easy things, done right, avoided a lapse.

When you must claim "not today"

Commercial schedules are actually ruthless, which is awful opportunity to risk on security. Weather, bad access, or missing out on components produce an appeal to press on. The workers top needs the authorization to say no. If the torque electric motor adapter shows hairline splits, it carries out not operate. If the grout plant falls short a pressure check for micropiles, production stands by. If the wall surface braces are low as well as you will preload tieback anchors, someone brings more shoring. These are actually not theoretical. I have taken crews off for super near a crane, blown hoses along with abject sheathing, as well as wall surfaces that carried out certainly not appear straight when we filled all of them to validate tieback capacity. Each delay experienced very painful for a day as well as forgettable a year eventually. The traumas our experts avoided would certainly have lasted much longer.

Documentation that feeds protection, certainly not bureaucracy

Good information supports very clear interaction and repeatable performance. Twist logs, port pressure logs, grout tickets as well as quantities, heap as-built locations, and also photos of affixing as well as bandaging are certainly not busywork. They provide the following team a standard, permit the engineer to readjust on real records, as well as create instruction concrete for brand new hires. When a close to skip happens, create it up along with specifics. If a cotter pin walked out, talk to why: wrong pin, vibration, or even unsatisfactory engagement. Take care of the origin as well as fold it right into the following morning's huddle.

Keep gradation files current. Torque tools, stress determines, and also tons tissues drift. Uncalibrated equipments make both safety and security and also premium dangers. A contractor that supplies clean records makes trust with customers as well as inspectors, which reputation purchases teamwork when you need to have an area change.

Special factors by unit type

Helical heaps are actually reliable in limited-access locations as well as delicate sites due to the fact that they create marginal vibration and also spoils. Protection rests on torque control, positioning, as well as section management. Wear on square-shaft couplers or round-shaft screws need to be actually tracked. A coupler failing under load sends power someplace. Change components through hours as well as evaluation, certainly not by hope. On steep websites, check equipment https://www.unitedstructuralsystems.com/barrington/ security before rotation, since the travel scalp can take a tiny device off line as twist climbs.

Resistance stacks depend upon reaction. The two hazards that appear the best are unsafe frames as well as overpressured tubes. If the frame slides or changes under bunch, stop. Get the bottom, broaden bearing, as well as recheck. Learn crews to bleed pressure before any wrench touches a suitable. Engage securing dog collars and also secondary restraint on ports to make sure that a gas failure performs not drop the tons suddenly.

Micropiles include boring liquids, air, as well as cement grout, each with its own risks. Air-mist drilling may inject penalties in to fractures, after that blast when a void collapses. Use guards, covers, as well as a prepare for cuttings record. Reinforcing cages are hefty as well as unmanageable. Rig them with spreader pubs and also never ever reach into a put on hold load. During high-pressure grouting, stand up free from the degree of installations as well as keep body system components away from possible water leak aspects. Concrete burns are actually genuine; clean stations as well as understanding matter.

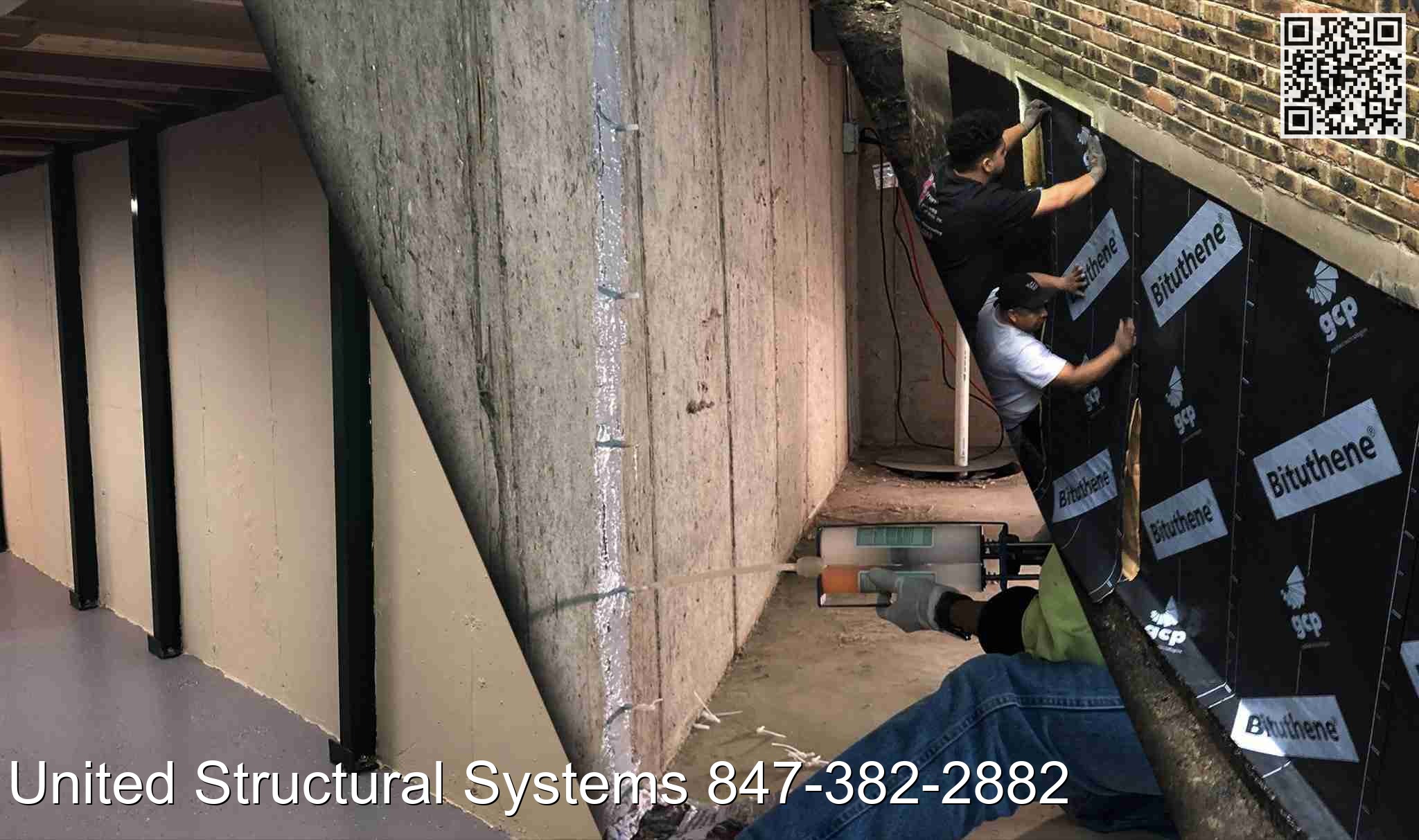

Helical tieback anchors bring interior and exterior work together. Inside, secure laborers coming from dust, noise, and wall structure particles. Outdoors, defend utilities as well as neighboring structures. The placement of the tieback governs where the bound duration properties, and small errors at the wall come to be huge misses out on at depth. Make use of an overview sleeve at the wall surface as well as a jig for angle management. When put in, tons exam and also lock-off ought to comply with the engineering spec precisely. Rushing lock-off bring about inconsistent preloads and sometimes splitting that sends you into foundation crack repair method, which no one budgeted or wanted.

Short field check-list that makes its own keep

- Verify electrical clearance at each heap or even tieback place, including personal locates as well as potholing where needed. Inspect drive head, adapter, pins, hoses, assesses, and torque or stress instrumentation. Substitute doubtful components now. Establish and impose a measured area around the rotation or jack location, along with one marked associate inside. Confirm interaction: that refers to as torque or even tension, devices used, stop-work indicator, and also broadcast or palm signals. Review recognition requirements and limits with the crew: aim at twist or even stress, intensity selections, verification and lock-off actions, and also what triggers a stop.

Building a society that lasts longer than a project

Even the very best treatments break without a lifestyle that values speaking out. The driver should take a worker's deter call without pride. need to compensate vigilance, not simply development. Celebrate the work that finished with zero injuries and also well-maintained logs, not merely the job that trumped the routine by a day. When turn over happens, pair brand-new hires along with steady palms. Let them invest a week tailing during the course of a mix of job: commercial helical pile installation outside, tieback anchors in a basement, protection turn in limited fourths, and a day at the micropiles vegetation. Cross-training widens judgment and also disperses safe routines all over systems.

Clients notice. When a crew relocates with purpose, maintains the website well-maintained, and also performs on its own properly, owners and also GCs ask you back. You become the professional trusted with deep foundation repair under critical procedures, the one welcomed to resolve structural foundation repair problems without producing brand-new ones. That track record is constructed in small selections: the ideal handwear covers, the noise of somebody calling torque precisely, the silent second when the operator breathes before interacting the drive.

Safety in pile job is actually certainly not a theoretical market value. It is actually congruity, attentiveness, and also the desire to decelerate at the correct seconds. Learn so the staff comprehends the why behind each measure. Put on PPE that matches the risks of switching steel as well as constrained systems. Adhere to procedures that transform changeable ground in to expected job. Do those three points, as well as industrial helical piles, helical anchors, resistance heaps, tieback anchors, as well as micropiles become trustworthy resources for commercial foundation stabilization, not resources of risk.